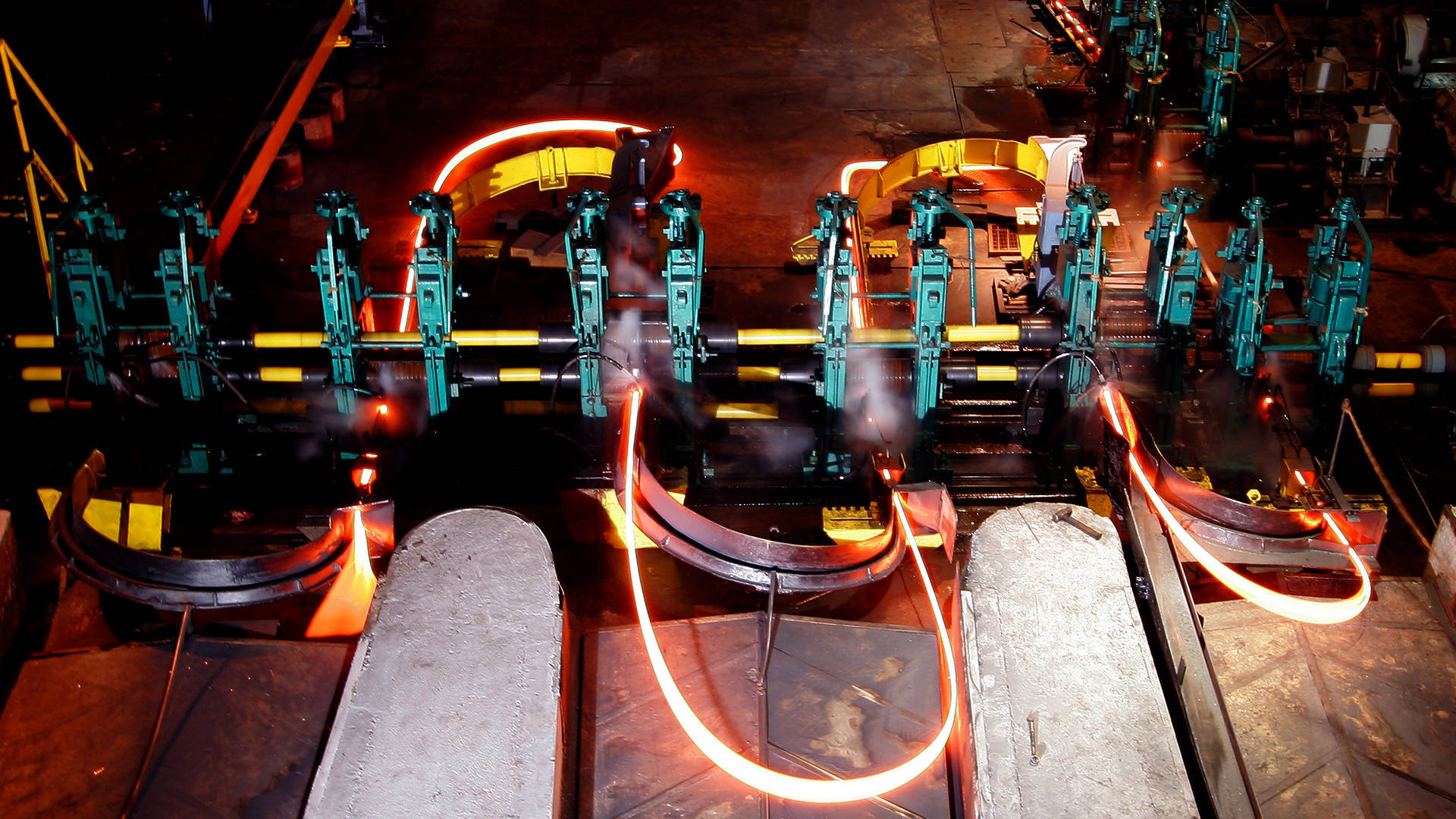

We are the manufacturer of

TMT Bars

Shri. Karvir Nivasini Mahalaxmi Ispat Pvt. Ltd. is a factory unit situated in the Gokul Shirgaon MIDC of Kolhapur. Being the first unit in Southern Maharashtra to manufacture TMT Steel bars, the brand Mahalaxmi TMT Bars is known for its quality assurance in the construction industry.