Strength

Mahalaxmi TMT Bars are of unwavering quality that makes them Earthquake Resistant.

Mahalaxmi TMT Bars are of unwavering quality that makes them Earthquake Resistant.

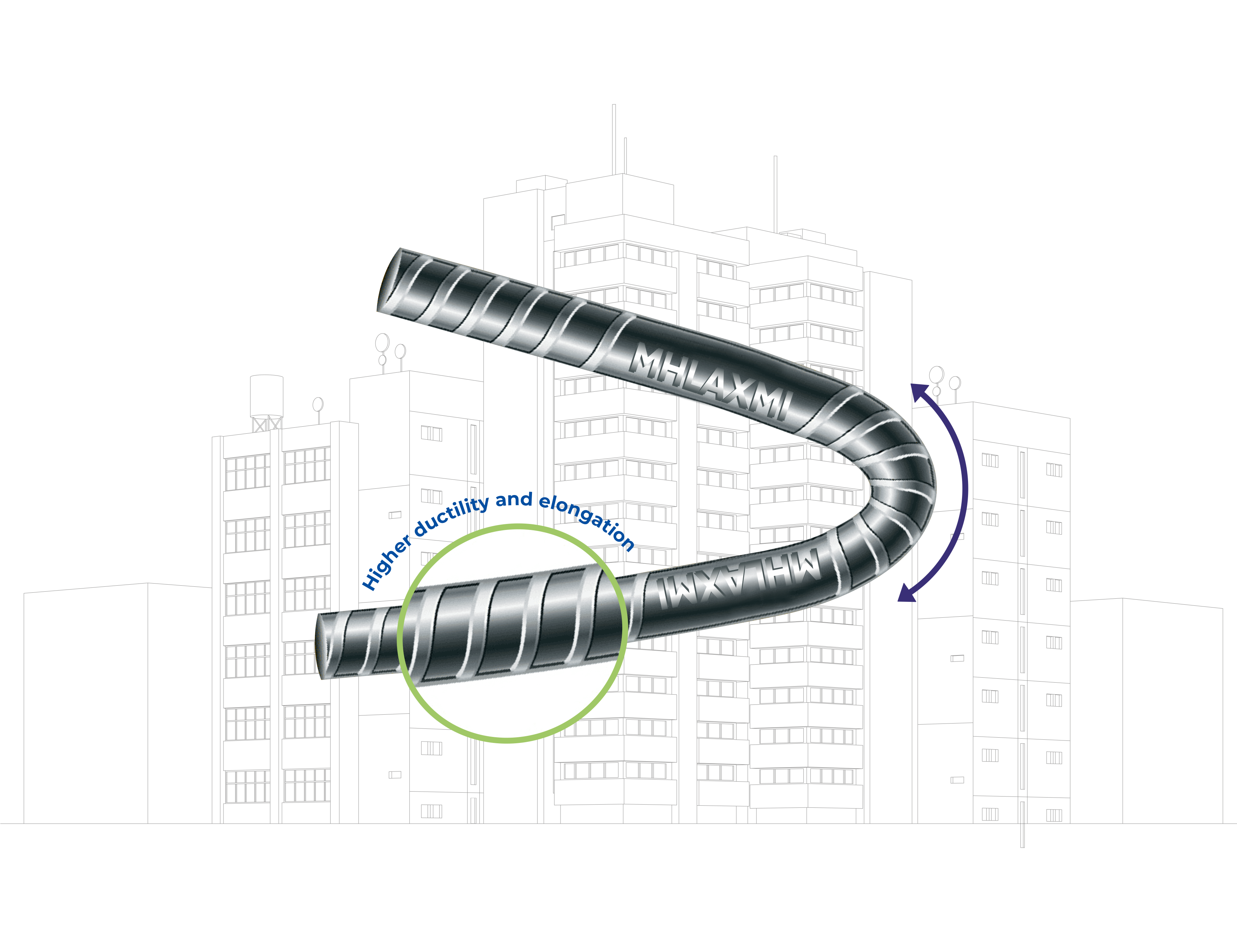

Mahalaxmi TMT Bars have higher ductility and elongation of up to 16%.

Mahalaxmi TMT Bars surpass IS-1786 : 2003 specifications and come with a 100% Guaranteed Replacement.

The chemical composition of Mahalaxmi TMT Bars assures fire resistance and corrosion resistance.

Mahalaxmi Thermo-Mechanically Treated bars undergo a process that has evolved from studies of the behavior of iron under stress & strain. Through deformation, the round bar’s section is reduced at various intervals and this results in increased strength uniformly across the bar. Thereafter, rapid quenching of the hot bar with cold water results in a phase change of the microstructure of the iron bar. The phase of the inner core of the bar is known as “Ferrite-Pearlite” which is responsible for the bar’s ductility. Whereas, the phase of the Outer Surface is known as “Martensite” which is hard and is responsible for the bar’s strength.

TMT bars are also known for their surface design. Mahalaxmi TMT Bars are uniquely designed to have ribs & lugs at a particular angle to get the best bondage with concrete. The spacing of the lugs on the bars is important as it defines its bondage with the surrounding concrete. Each bar is branded with embossed letters at every meter length stating our brand name, the ISI marking, the Grade of the bars, and the License number issued by the Bureau of Indian Standards in the format like “Mahalaxmi ISI 500 752078”.

Mahalaxmi Bars come in a standard length of 12.2 meters (40 feet). However, to avoid the wastage of material on the construction site, Mahalaxmi bars are also available from 3 meters (10 feet) up to 24 meters (80 feet) in length known as the Cut-Length Bars. Using Cut-Length bars will help avoid Lapping Joints which are usually seen in higher diameter sizes and are about 1 meter in length. Using Cut-length bars helps save up to 15% on the cost of construction.

The chemical composition of the Mahalaxmi bars is very accurately checked and verified by the Optical Emission Spectrometer at our in-house Laboratory. The importance of this is very critical because the chemical composition of elements such as Sulphur and Phosphorous is to be very precisely controlled. Similarly, the weight-per-meter (WPM) of the bar is also important because a higher WPM will negatively result in shorter lengths of bars and adversely cost more. Mahalaxmi bars have a 2% under-tolerance WPM that provides the same grade but more length of bars. Our fully equipped in-house laboratory ensures that each batch is correctly manufactured to its best capability and within the limits of the specified standards.